Electrosurgical technology on the international stage 1962-2003

In 1962, the first sales office was opened in Cologne, with more to follow in Munich, Hamburg, Krefeld, Hannover, Frankfurt and Nuremberg.

Helmut Erbe (1928-2023)

Helmut Erbe joined the family business in 1945 as an apprentice. In addition to managing the company, his father Otto was involved in politics on an honorary basis, as well as in the democratic reconstruction of the country during the post-war period. Helmut Erbe was involved in the responsibilities of the company at an early stage.

In 1962, when he assumed sole responsibility for managing the company, he focused on development and production in the field of electrical medical applications – and on establishing a nationwide sales network in Germany followed by an international sales network. In 1962, the first sales office was opened in Cologne, with more to follow in Munich, Hamburg, Krefeld, Hannover, Frankfurt and Nuremberg.

In 1968, the first foreign subsidiary was established in Vienna. During Helmut Erbe's reign, six further foreign subsidiaries were established in France, Switzerland, the Netherlands, the United States (in Georgia), Poland and the United Kingdom. As international success grew, so, too,

did the need for space - in 1985, the significant step was taken of moving to an industrial park on the outskirts of the city: Erbe established what is now the company headquarters in Waldhoernlestrasse, in the Tuebingen district of Derendingen.

Under his management, this medium-sized company set international benchmarks with its innovations. The close international collaboration with clinics, universities and third-level educational facilities ensured the necessary market edge. Erbe helped set the pace of the rapid developments in operating theaters and medical practices.

In 1996, Helmut Erbe incorporated the fifth generation into the management of the company in the shape of his son Christian Otto Erbe and son-in-law Reiner Thede. When the "senior member" finally retired from the management of the company in 2003, he had been active in the company for almost 60 years and had laid solid groundwork for the future of the family business.

From 1954 onwards, Erbe produced the Erbotom Multiplex, an electrosurgical unit that combined two generators, enabling universal use in all medical fields. Subject to continued refinement, the Erbotom Multiplex remained a leading company model for decades under the management of Helmut Erbe.

The image on the left shows the first Multiplex; on the right, a model from the 1970s is shown in the new design. This was another instance where Erbe successfully broke new ground: in 1961/62, Professor Tomas Maldonado and a project group at the Ulm College of Design developed a completely new and unmistakable appearance for Erbe equipment as part of a pioneering project. Long before "corporate design" had become an established commercial term, the experts in design from Ulm developed an ergonomically constructed housing with user-friendly switches and pictograms, as well as designing a new logo.

At the beginning of the 1980s, the age of tube-based equipment in electrical medical applications had finally passed. The devices were being built using powerful transistors. One of the first units in the successful T series was the 400-watt Erbotom T 400 C. In 1985, Erbe was the first manufacturer in the world to design a self-regulating electrosurgical unit, the Erbotom TUR. Its development was based on microprocessor technology and on a new type of generator, and represented a milestone in the history of the company. It was used for the surgical removal of parts of the prostate via the urethra.

Cutting and coagulation, automatically regulated by microprocessors – this was the technology upon which Erbe developed the ICC series in 1992: "Intelligent Cut and Coagulation" was the regulated electrosurgical cutting procedure that made the company a leader internationally in electrosurgical technology. By monitoring different values during endoscopic surgery, the ICC units guaranteed doctors optimum cutting as well as controlled staunching of blood, while also ensuring minimum tissue damage. With more than 80,000 units installed, the ICC series became the most successful range of electrosurgical generators ever produced by Erbe.

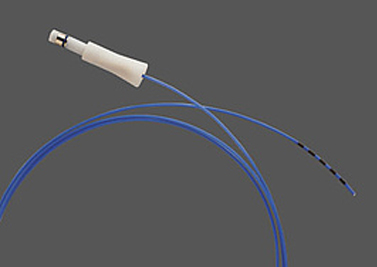

In 1995 in collaboration with the surgeon Professor Karl-Ernst Grund of Tuebingen University Hospital, Erbe developed the first flexible probe for use in argon-plasma coagulation (APC) in endoscopic surgery. A number of years later, with Martin Hagg as development manager, a membrane filter was integrated into the APC probe that prevented any backflow of blood or secretion and thus any contamination of the probe. The filter is integrated as a fixed component into the APC probe, in the same way as the connecting cable. Argon-plasma coagulation is particularly suited to surface staunching of blood as well as to devitalization of tissue. For this purpose, the current is routed to the tissue via an ionized jet of argon gas, without any direct tissue contact. The procedure is suited to the staunching of blood following injury or biopsies, or for use in the case of certain tumors.